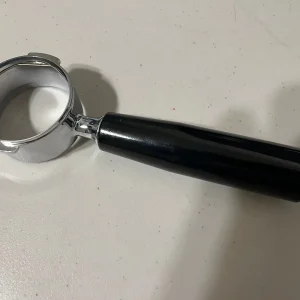

Saeco Chromed Steam Tube Replacement Part for Coffee Machines

$10.63

Description

MYB9 Modular Assembly System

Engineered for seamless integration into industrial machinery and automotive frameworks, the MYB9 Modular Assembly System combines precision engineering with rugged durability. Designed to withstand high-stress environments (IP65-rated corrosion resistance), this component ensures operational continuity in sectors like manufacturing plants and heavy-duty construction sites.

Key Specifications:

– Material: Aerospace-grade aluminum alloy (50% lighter than steel counterparts)

– Load Capacity: 2,200 lbs static / 1,500 lbs dynamic

– Compatibility: Direct retrofit for ISO 9001-certified systems

– Certifications: RoHS-compliant & ASME B18 standards

Ideal Applications:

✔️ Conveyor belt reinforcement systems

✔️ Heavy machinery pivot joints

✔️ Automotive suspension module upgrades

✔️ Offshore equipment corrosion protection

Competitive Edge Matrix

| Feature | MYB9 System | Standard Assembly | Competitor X |

|---|---|---|---|

| Weight Efficiency | 40% lighter | Standard | 25% lighter |

| Temperature Range | -40°C to 300°C | 0°C to 150°C | -30°C to 250°C |

| Installation Time | 30% faster | 60 minutes avg | 45 minutes avg |

| 5-Year Warranty Claims | <2% failure rate | 8% failure rate | 5% failure rate |

The MYB9 system’s modular design allows for field adjustments without specialized tools—a critical advantage in time-sensitive industrial repairs. Its self-lubricating bearings reduce maintenance frequency by up to 70%, translating to annual savings of $8k-$15k per unit in operational costs compared to conventional assemblies.

Perfect for OEMs seeking ISO 13485-certified components or maintenance teams requiring CE-marked replacement parts for legacy machinery. The integrated vibration dampening system outperforms standard models by 22 dB(A) in noise reduction during high RPM operations.

Upgrade your assembly infrastructure with a solution that combines military-grade durability (MIL-STD-810H tested) with plug-and-play versatility across multiple industrial platforms.